Intentionally designed

Design

Working together with The Department of Civil Engineering at McMaster University, our product team researched numerous mix designs using polymer modifiers and fiber reinforcements.

Once the mix properties were optimized, work focused on product design to improve product performance and durability requirements. Engineering tools such as FE and plane frame models were used to analyze and develop designs for various architectural profiles and mouldings. The rigorous numerical analyses were then validated by product and system testing of various designs for product applications typical of architectural precast.

What Makes NEOCAST™ Product Different?

Lightweight

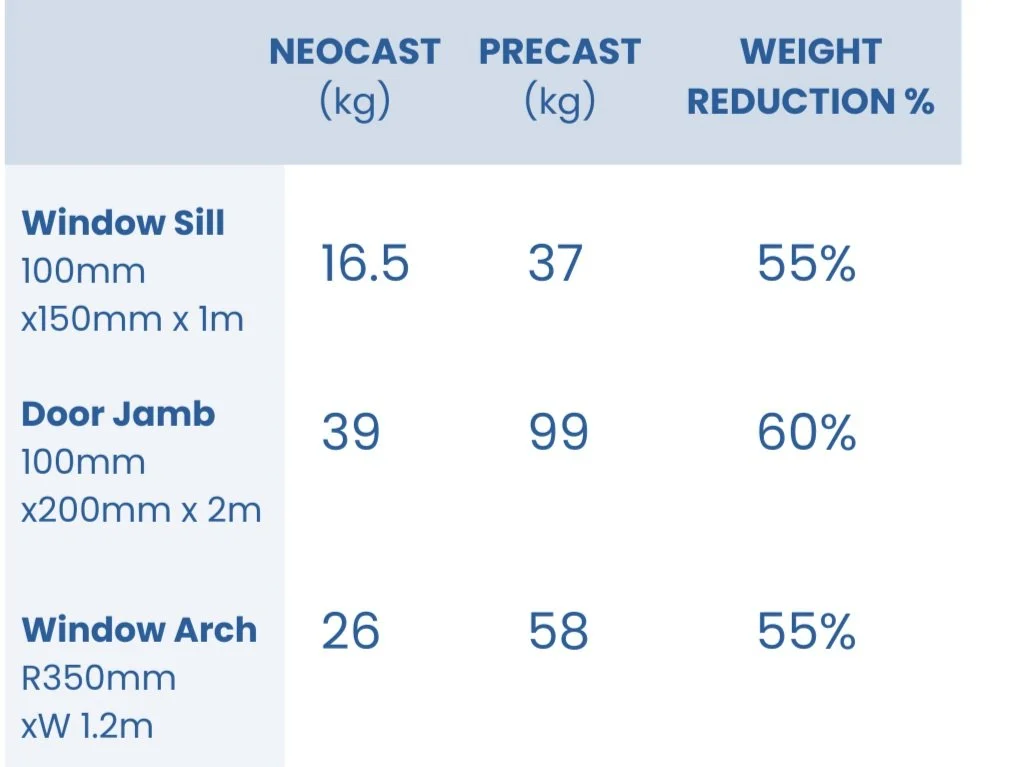

NEOCAST™ product can weigh up to 55% less than comparable solid concrete products. This lower weight allows a mason to easily handle and lay our product with improved onsite efficiency, reducing valuable installation time. The lighter weight also reduces time of delivery, provides greater design freedom and, with less material, reduces the environmental impact.

Strong

NEOCAST™ product is produced with an engineered high performance cementitious mix (HPC) that is 2-3 times stronger than ordinary concrete. The combination of strength, durability and aesthetics are due to an integrated fibre matrix and combination of finely graded raw materials selected for their optimized size distribution and chemical characteristics. The excellent mechanical properties in both flexural and compression strength allow for the manufacture of thin-walled sections that offer lighter weight while still meeting and exceeding performance requirements.

Durable

NEOCAST™ product has been developed with a dense matrix structure that provides exceptional durability. NEOCAST™ product is designed to meet and exceed all applicable durability requirements set by Canadian construction standards. Our NEOCAST™ mix is formulated to resist efflorescence and its low absorption characteristic renders the material repellant to most aggressive agents.

*NOTES: Standards Used to Test for Material Properties: ASTM C109 for 1 and 28-day compressive strength; ASTM C348 for 1 and 28-day flexural strength; ASTM C157 for shrinkage; ASTM C1403 for water absorption; Modified RILEM TC176/ASTM C1262 for freeze/thaw. The reported values are for guidance only and cannot be used as technical design specifications. Performance is dependent on the product characteristics, raw materials, manufacturing procedures and equipment used. This data provides no guarantee or commitment that the values will be achieved in any particular application of NEOCAST® product.